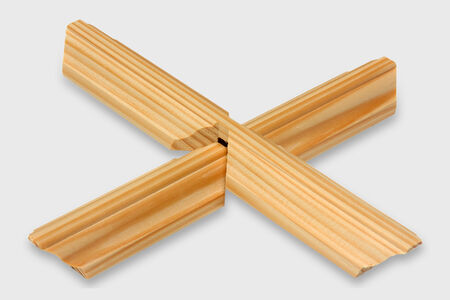

Cross joint milling technology from the market leader

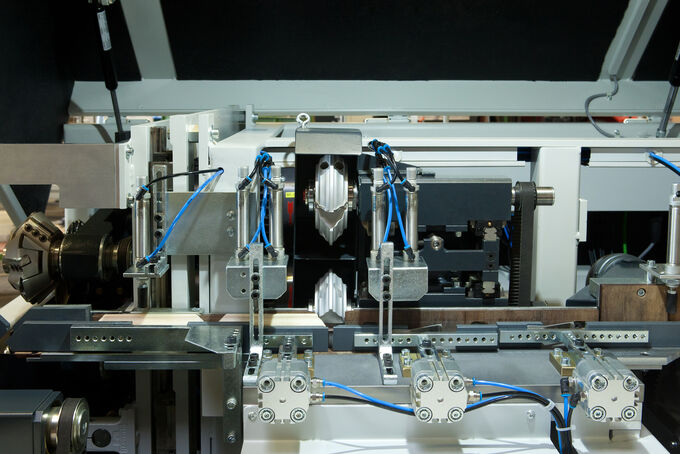

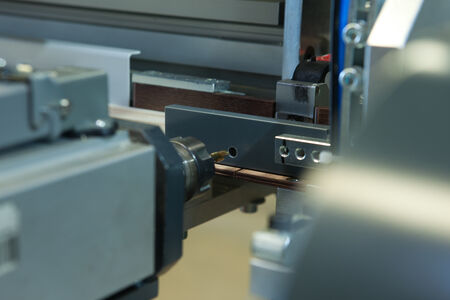

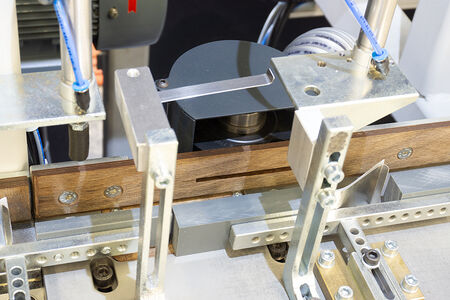

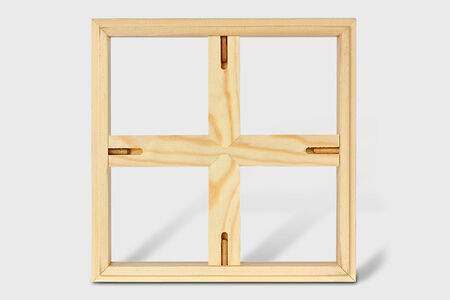

The KSF-2E is the world’s leading CNC-Special Milling Machine for the fully automated manufacture and complete processing of high-quality cross joints and grilles in the series production of glazing bars windows and doors.

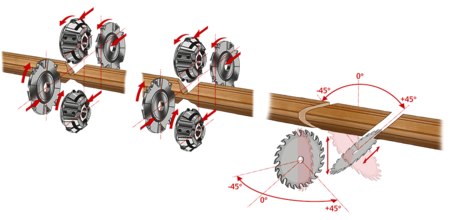

With up to eight aggregates, the machine produces cross joints from wood, aluminum, MDF or PVC bars in excellent quality and processes all components of a glazing bar grille perfectly.

Operations

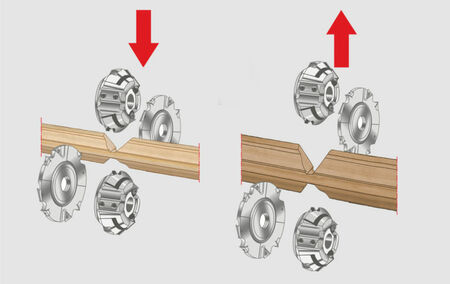

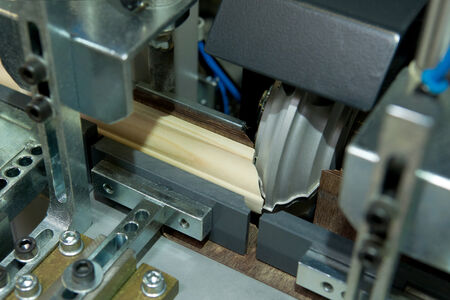

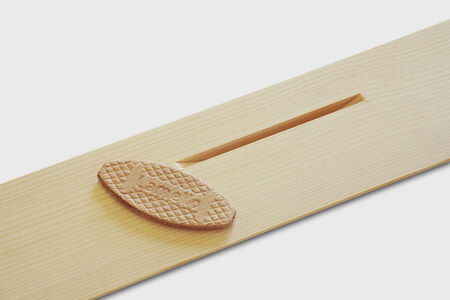

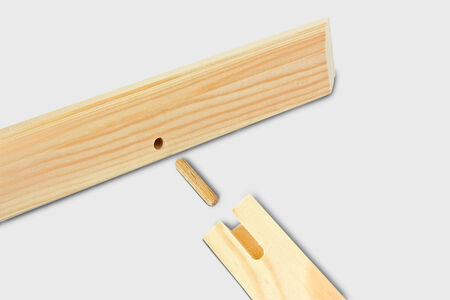

- Manufacture of cross joints in the most diverse executions and sizes.

- Coping of the glazing bars ends.

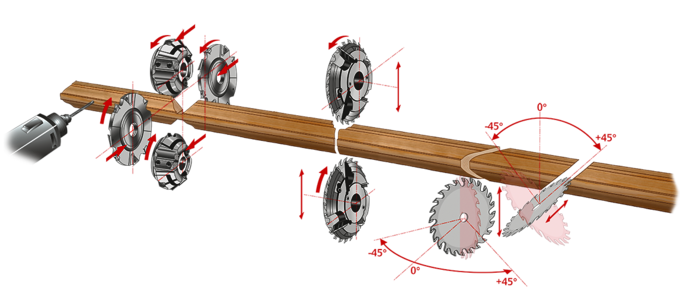

- Cutting to length of glazing bars at different angles.

- Cutting to length of glazing beads at different angles.

- Cutting to length of frame profiles.

- Drilling of fastening holes for glazing beads.

Characteristics and technical features

- Available in various customized executions and with special aggregates.

- Also availabe in special execution for the manufacture of „historic“ cross joints (for authentic restoration jobs)

- The cutting and drilling units can be mounted vertically and/or horizontally.

- Easy adjustment to different profile widths with the automatic height adjustment of the milling aggregates

- Wireless measuring wand for transmitting the lite size of glazing frames directly into the machine program.

- Very short processing time.

- The machine operator can create new macros by himself and optimize the KSF-2E at any time or adapt it to new production requirements.

The complete systems for milling profiled bars for cross joints in one machine

Downloads

Cross Joint Milling Machines made by SHM Stegherr: Global leaders for good reason.

Your contact person

Sales & service

Rainer Böhm, +49 9402 501 22

Sales & service international

Aldona Piecha, +49 9402 501 23

Sales & service international

Ulrike Gahr, +49 9402 501 27

Contact form

Have you got any questions or would you like to inform us on something?

We look forward to receiving your message.